In this whitepaper 8 powerful pump questions are asked which have proven to be the key factor in making the right choice.

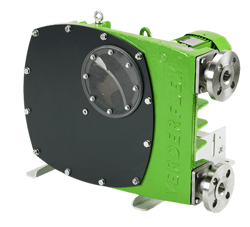

Hose pumps can circulate slurry SGs of 1.6 to 1.8 or up to 80% solid content. The traditional centrifugal pump loses efficiency when the slurry SG reaches 1.3 or 30% solids. With this limitation, slurry pumps have significant process water demands: on a plant processing 75 tonnes of ore per hour, and at 65% solids. Every time a hose pump replaces a process slurry pump, it saves over 1,100 million litres of water annually because of the slurry pump’s inefficiency. On the same duty, the hose pump requires less than 25% of the process water of a slurry pump.

On the same 75 ore tonnes per hour plant, on thickener underflow duty at full flow, a VF125 hose pump absorbs around 35 kW whereas a slurry pump needs over 70kW: a saving of over 50%. This directly translates into reduced electrical requirements. Power rationing is a concern for many established mines, on new developments the infrastructure costs to import power can be considerable and can even cause significant delays and generate considerable non-mining environmental opposition.

There is also a significant economic case – in the above example, the hose pump reduced annual operating power demand by over 210 MWh.

Peristaltic Pumps Increase Downline Efficiency and Reduce Overall Plant Size

Pulp density is critical to optimum plant performance, an increased solid content can reduce the number of post thickening filter stages, saving on the initial capital cost and reducing the footprint of mineral processing operation.